Silage hygiene – avoiding reheating

In addition to the factors for achieving good basic forage quality during ensiling, the management of the silage face of grass and maize silages is another important factor in maintaining stable silage. Open silages are exposed to weather-related influences, especially in autumn and winter. Rain, snow and strong sunlight are often the cause of dirty silage surfaces and hygienically questionable silages. SCHAUMANN gives you tips on successful silage management.

Tip 1: Remove residues

Remove loose material from the silage face. Soiled silage residues from previous extractions can contaminate the silage windrow and lead to reheating. This becomes particularly clear with a thermal imaging camera in figure 1. The left figure shows a clean silage face, the silage on the right is heated by residues on the silage face.

Tip 2: Do not excessively cover the silage windrow

The seepage of rainwater or snow into the silage pile leads to mould growth and spoilage of the silage. This is partly because oxygen gets into the silage from above and partly because the rain washes out the stabilising fermentation acids into the layers further down. Strong sunlight dries out the silo surface, making it more susceptible to reheating and mould. You should prevent this at all costs and avoid covering the silage "in advance”, but always only as needed.

Tip 3: Prevent air from entering between the silage windrow and the covering film.

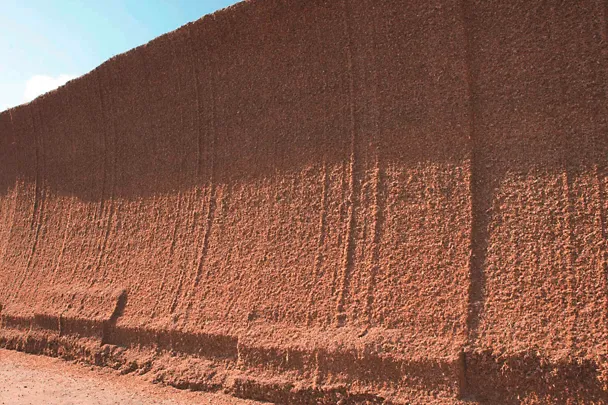

Sardine technology for sealing the opened silage

Particularly in the case of silage windrows that lie in the main wind direction, you should erect an oxygen barrier that "travels" with the silage. This can, for example, consist of sandbags placed as crossbars or even more effectively as longitudinal bars (sardine technique) at the height of the cut (see picture). Each time the silage is covered further, the barrier must be placed further back. In this way, you prevent air from entering between the silage sheet and the silage windrow. Air ingress promotes the development of yeasts as well as moulds and leads to reheating.

Tip 4: Temperature control at the silage face

Before each silage removal, measure the temperature of the silage face at predetermined points with a commercially available insert thermometer or a thermal imaging camera. This ensures you are able to quickly recognise any reheating and react with suitable conservation measures at the silage face and in the feed ration before yeasts and moulds spread to deeper silage layers.