BONSILAGE maize silage products help avoid expensive DM losses

Silage losses on German farms are often far too high. LFL Grub comes to this conclusion in the context of a balancing study on silage losses. Special combinations of homo- and heterofermentative lactic acid bacteria in BONSILAGE products for maize silage avoid these losses and earn the operation money.

Alarming results on ensiling trials of LFL Grub

Between 2010 and 2012, LFL Grub (Brigitte Köhler, Dr. Hubert Spiekers) conducted a study on the highly explosive topic of ensiling losses between field and trough on test farms in Bavaria. Grass silages were examined on 26 farms and maize silage on 18 farms. The basic principles are the precise weighing of harvested crops taken from the field and brought into the silo as well as the recording of the amounts fed from the feed mixer wagon. Grass silage losses averaged just over 9% and the numbers fluctuate between 2 and 26%. For maize silage, the average losses were estimated at a good 10%.

The causes of silage losses must be differentiated

It is known that low losses due to residual respiration and the actual ensiling process occur during the storage process of silage. These losses are considered unavoidable and are rarely below 3 to 5%. In addition, losses may occur due to ineffective or undesired ensiling processes under the film as well as after reheating processes after opening the silo. These effects can absolutely be avoided by proper silage management and the use of suitable silage additives.

Avoidable losses on farms are high

Assuming that the 9-10% losses previously determined in the LFL Grub trial correspond to the actual resources of the operations, there is still an avoidable loss ratio of 4-7% after deducting 3-5% of unavoidable losses. Once larger reheating problems are added, orders of magnitude of 20% losses and more are quickly achieved. In addition, it must be remembered that the losses found are fresh mass, losses in weight. The energy losses occurring during reheating exceed the weight losses again significantly.

Example calculation shows the following: Businesses give away cash

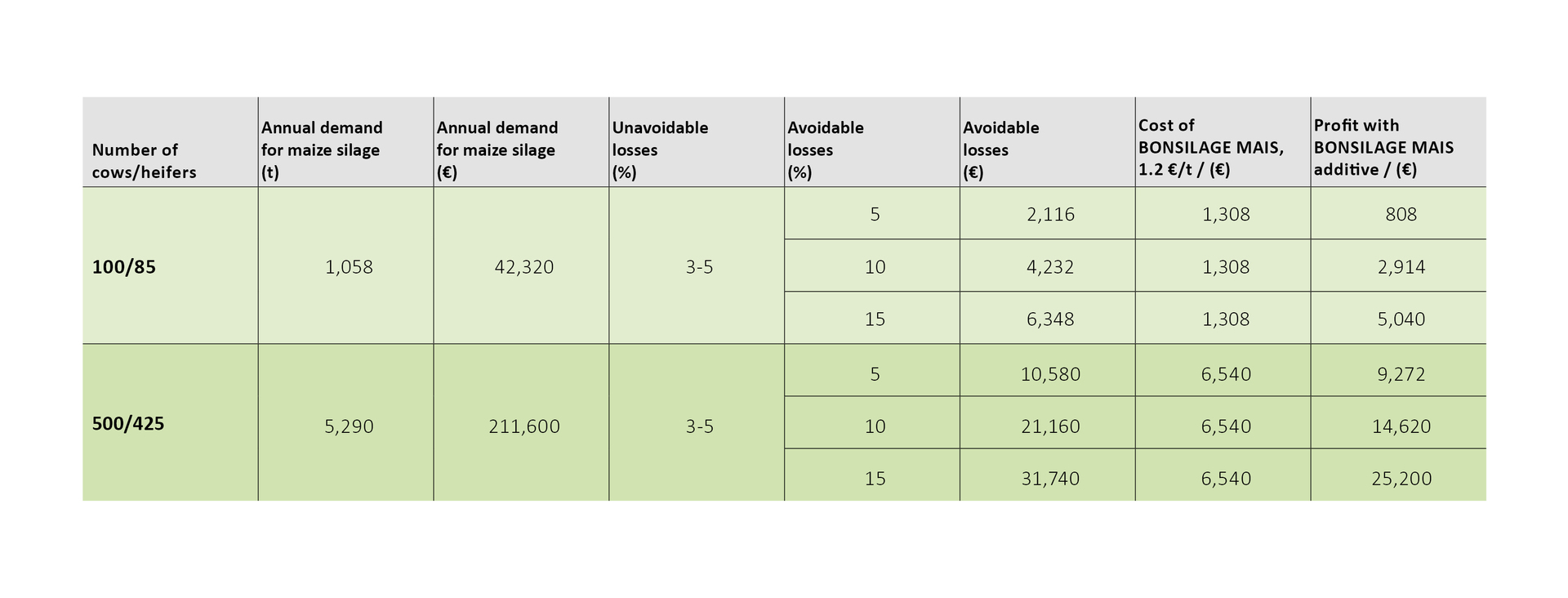

A monetary valuation and example calculation shows (see illustration), that business are thus giving away cash. LFL Grub puts the annual consumption of basic feed silage on the example of a farm with 100 dairy cows and 85 calves at 2,115 t FM. Assuming that 50% of the staple feed consists of maize silage, 1,058 tonnes of corn silage are needed. At an assumed price for maize silage of € 40/t silage, the value of the silage is € 42,320. With assumed costs per tonne of € 1.20 for treatment with BONSILAGE MAIS, for example, this corresponds to the example calculation of € 1,308 for the silage additive. Depending on the assumed amount of the avoidable loss rate, the stake leads to a profit between € 808 and € 5,040.

BONSILAGE products for maize silage are worth the money

The ‘investment’ in a suitable BONSILAGE product for maize silage (BONSILAGE MAIS, BONSILAGE SPEED M and BONSILAGE FIT M) therefore pays for itself from a loss reduction of approx. 3%. Numbers that are usually reached as well. All additional effects, such as better digestibility of the aerobically stable, hygienically perfect silage or simply the saving of work (such as by sorting out incorrectly fermented silage) are not yet considered in this calculation.

Example calculation for silage losses in maize silage depending on the size of the operation*