A good feed structure for piglets

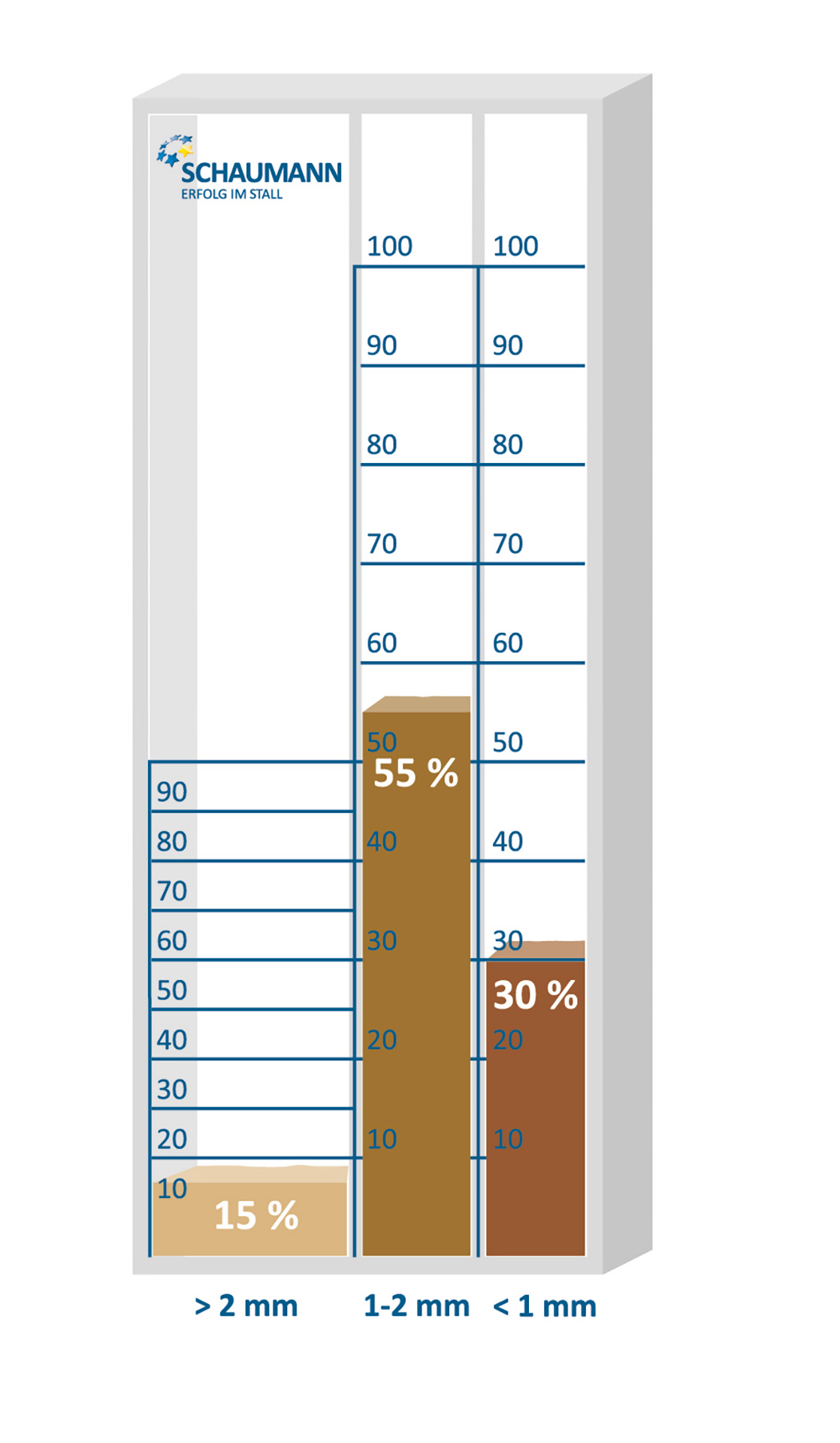

When we talk about feed structure, we are referring to the degree of grinding of the complete feed for piglets. More specifically, we are referring to the particle sizes and particle size distribution in the mixture.

How can the feed structure for pigs be checked?

Darst. 1: Empfohlene Futterstruktur in der Ferkelaufzucht

However, even in compressed feed, it is possible to make at least a rough estimate of whether the feed structure has been taken into account. If the crumbs can be crushed and fragments of the grain used are visible to the naked eye, then a coarser feed structure has been successfully achieved even in the compressed product. However, this requires a very special technique, starting with the mill and its settings and continuing through to the die on which the crumbs are produced.

Why is a coarser feed structure advantageous?

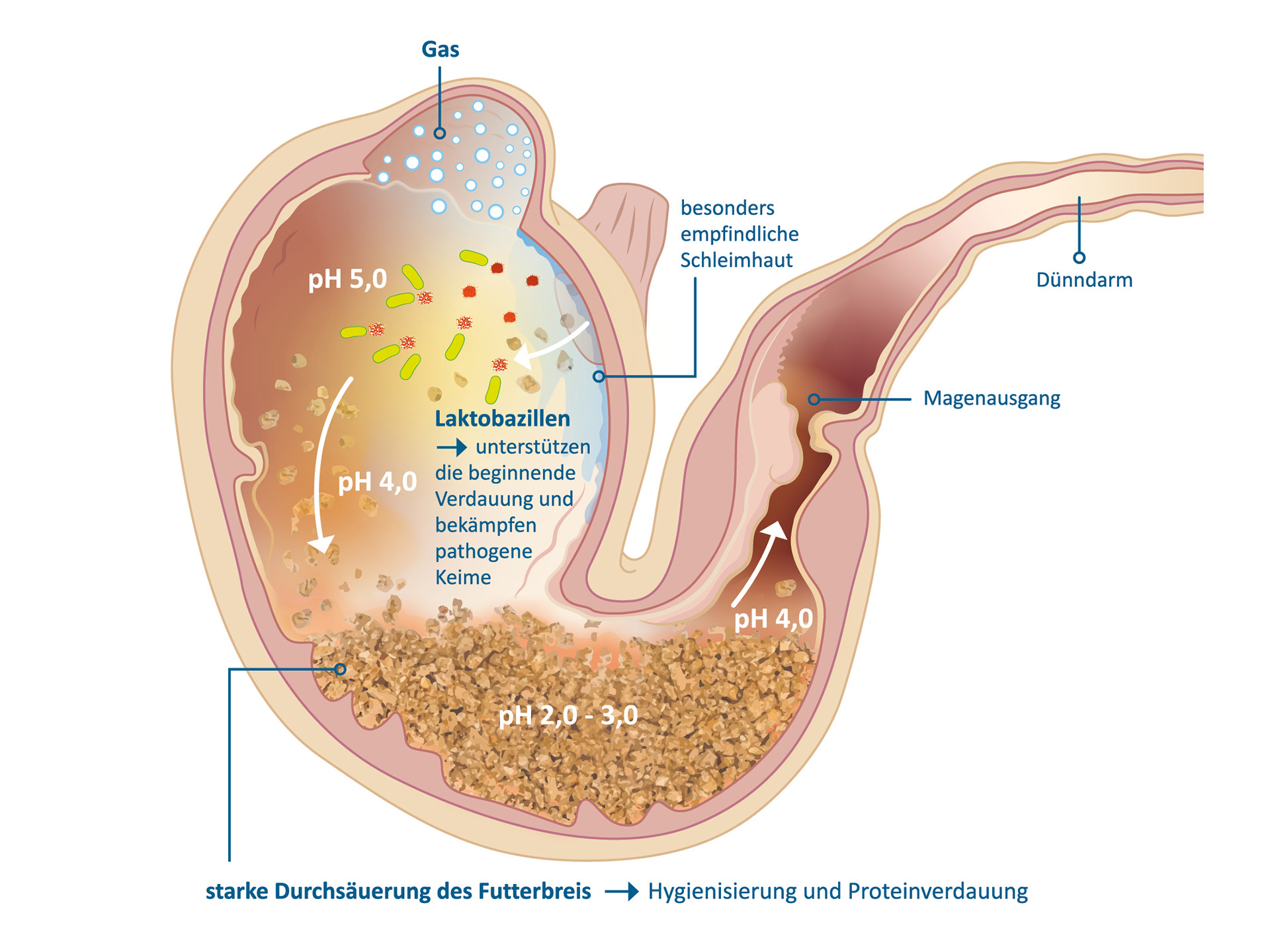

Even in the pig's stomach, the feed structure has an influence on the health and function of the organ. Ideally, the feed in the stomach should have a mushy consistency like rice pudding. Only then can individual layers form in which different processes take place

Darst. 2: Verdauungsprozesse im Schweinemagen mit grober Futterstruktur

Lactobacilli are particularly active in the upper part of the stomach (see Fig. 2). These bacteria help to render any pathogens that may have been ingested harmless in the stomach. In addition, a kind of fermentation of the food begins here, which aids subsequent digestion.

At the bottom of the stomach, the food pulp is mixed with hydrochloric acid, which is produced by the stomach itself. The low pH value sanitises the food. In addition, the enzymes produced by the stomach lining to break down proteins are only active in this acidic environment. The digestion of plant proteins can only begin in the stomach when the pH value in the food pulp falls below 3.

The main task of the stomach is therefore to prepare the food for further digestion in the intestine. In addition, the stomach ensures that pathogenic germs do not reach the intestine (stomach barrier).

What happens when feed is ground too finely in the stomach?

If, on the other hand, the feed is finely ground, the feed pulp behaves completely differently in the stomach: the stomach contents then resemble a puréed soup. The thin consistency means that no stratification occurs and the different functional areas cannot develop.

As a result, there is no proper lowering of the pH value in the food pulp. Although the stomach now produces significantly more hydrochloric acid than with a coarse food structure, the pH value in the food pulp does not drop sufficiently.

Why do stomach ulcers often occur with a food structure that is too fine?

The entrance to the stomach has a particularly sensitive mucous membrane. To protect it, the pH value is very strictly regulated in this area. If large amounts of hydrochloric acid quickly enter this area through the liquid feed slurry, the mucous membrane has to take strong countermeasures – for example, by releasing buffering substances such as bicarbonate.

In the long term, however, this overwhelms the natural protective mechanism of the mucous membrane.

The result: If the feed structure is too fine, stomach ulcers often occur in the front entrance to the stomach of pigs.

Why is the right structure crucial?

In summary, a coarse feed structure ensures the health and functionality of the stomach. It enables the formation of different zones in which the feed is optimally prepared for digestion. At the same time, orally ingested germs are rendered harmless and prevented from entering the intestine in the first place.

Conclusion:

Those who regularly check the feed structure and, if necessary, adjust the mill settings or replace worn parts, are actively contributing to success in the barn.

It is not only self-mixers who can now take full advantage of a coarser feed structure. Thanks to the new careX factor, a coarse feed structure is now also maintained in our piglet rearing feeds.

Video: Checking feed structure with the SCHAUMANN sieve box

Adjust the privacy settings for YouTube to view this content.