Praktische Bullenfütterung

The financial gap between successful and less successful bull fattening farms has widened in recent years, partly due to high concentrate prices.

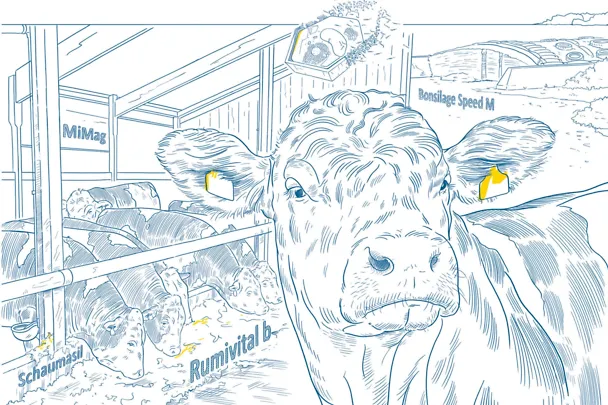

In comparison with the increasingly sophisticated feeding of dairy cattle, ration design for bull fattening often appears outdated. The ration often consists of maize silage, some straw, soya/rapeseed and grain, plus the cheapest possible mineral feed.

The changing ration requirements of bulls in the various fattening stages are often not taken into account. Ration design should take into account that daily weight gains are highest in the middle fattening phase and decrease slightly towards the end of the fattening period. The increasing feed intake in the later fattening phases must also be taken into account. This means that a reduction in the energy and crude protein content per kg DM in the ration as the fattening period progresses is necessary to meet requirements and is an economic must.

While the digestibility of NDF, a balanced RNB or the cation-anion balance (DCAB) are naturally taken into account in ration calculations for cows, these values often seem irrelevant for ration planning for bulls. However, many symptoms such as restlessness, foamy manure, excessive urination, thick faeces and poor feed intake point precisely to these values.

Forage is the key to success or failure

Silage quality is the biggest factor that bull fatteners can use to influence their economic success. It is important to prevent feed losses due to reheating, mould formation and lack of palatability, as well as energy losses per kg DM.

According to official figures, reheating silage alone quickly causes feed losses of around 10%. When feed is heated, feed intake often decreases, thereby multiplying the problem. The use of a silage inoculant such as bonsilage SPEED M not only prevents reheating losses through rapid yeast control, but the treatment also costs only a fraction of the losses. The monetary investment would already be recouped with a reduction in losses from 10 to 7%. This calculation does not yet take into account reduced concentrate purchases and improved animal health and performance. The old saying, ‘Corn silages itself!’ no longer applies in view of harsher summers and greater stress on corn stocks.

Selection-free feed presentation

Most bull fattening farms use feed mixers, but automatic feeding is also gaining ground. The major technical challenge here is the presentation of a non-selectable ration. The selection of the ration can lead to considerable problems. The highest-ranking animals pick out the concentrated feed, leaving the lower-ranking animals with significantly less. The bulls grow apart and scuffles at the feeding table can lead to injury-related losses.

Selection can be recognised by so-called ‘hole eating’ (see Fig. 1), by differences in faeces within a group fed the same diet, by occasional urine drinking and by joint and hoof problems, the latter usually occurring in the ‘most beautiful’ bulls. The latter has always selected the concentrated feed and developed acidosis-related problems in the long term, while the urine drinkers are usually the lower-ranking animals. These effects are exacerbated when the trough is empty for 1 to 2 hours once a day. Then there is a real race when the feed is put out again. This is not due to hunger, but is aimed at the concentrated feed.

Is there potential for savings with mineral feed?

In practical bull fattening, the economic consideration of the ration often ends with feed costs. Income above feed costs is not calculated.

The first reflex when faced with cost pressure is often to use a cheaper mineral feed. However, the cost breakdown in Figure 2 shows that this is often the smallest cost factor. The targeted use of, for example, ASS-CO-FERM live yeast to stabilise the rumen pH value or RUMIVITAL b to improve fibre breakdown, faster rumen passage and higher feed intake offers opportunities that pay off many times over. Which supplement is appropriate for which ration is determined not least by the quality of the silage. Alternatives in protein supply, e.g. with rapeseed meal, dried distiller's grains or even the targeted use of feed urea, can help with optimisation.

It is never worth cutting corners when it comes to mineral feed. With an average usage of 100 g per animal per day, a mineral feed costing €70/dt, for example, would amount to just 4 ct per animal per day compared to a cheap mineral feed costing €30/dt – not to mention the poorer nutrition for the bulls. SCHAUMANN's expert advice service offers transparent ration calculation, including feed costs per animal per day, to optimise your master feed results. It is not uncommon to save 30 to 40 pence per animal per day. Assuming around 500 days in the barn, this amounts to savings of £150 to £200 per animal, including top-quality nutrition with a high-quality RINDAMAST mineral feed.